ADAMOS series - Decommissioning - Technical Guide

Automated Drum Monitoring Systems - designed to scan radioactive waste materials coming from decommissioning activities.

Purpose of the article

The purpose of the present article is to provide a general description of the ADAMOS Series systems, to be used as a guide or simply as a reference information.

The document will describe each version of the system designed and assembled up to date. The assembly drawings will help the reader to understand the layout and the operative cycle of each version.

General description

ADAMOS is an automated Segmented Gamma Scanner station, designed to measure drums containing solid radioactive waste materials.

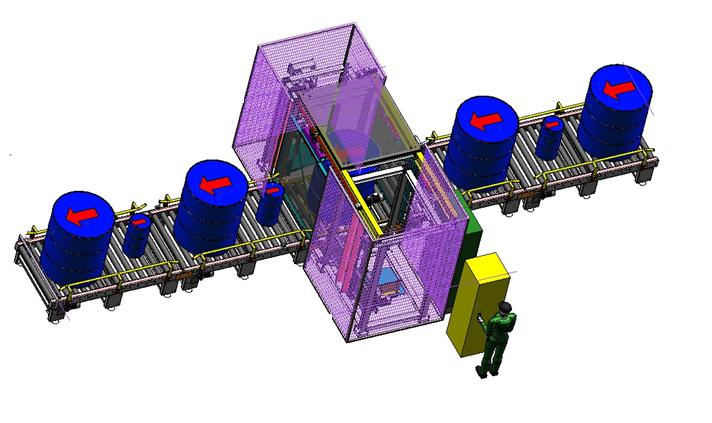

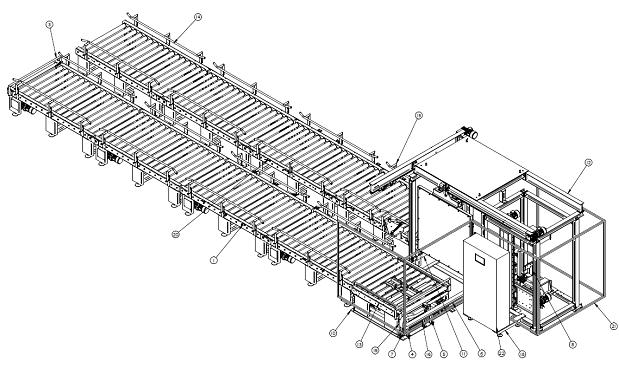

Its main parts, as they can be seen in the intro image, are:

- Mechanical structure

- Conveyors

- Measurement station

- Detection equipment

- PLC and PC

- Safety devices

A common feature that is found in all versions designed up to date, is the mechanical conveyors array used to load/unload the drums on the station. The conveyors are built in modular sections, so it’s easy to arrange them as required by the installation site and/or by other needs. The conveyors can be arranged in a rectilinear array, but eventually also bended paths are possible.

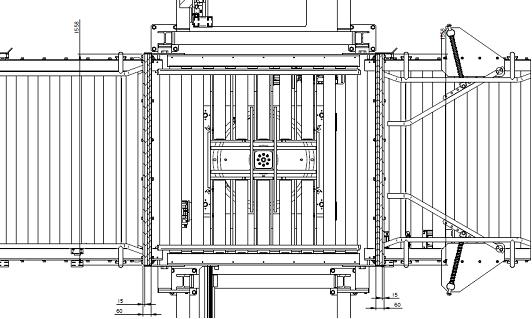

The measurement station is different between the ADAMOS versions, and different detection equipments can be used too. Nevertheless, the position in the mechanical structure is quite the same in all models: typically the measurement station is placed in the center of the conveyors array, between the load and the unload sections. Also, a centering device and a rotating platform can be found in all the measurement stations: they are used to place and hold in the proper position the drum carried by the conveyors, and to rotate the drum around its vertical axis so that the detection apparatus can scan all its volume and provide an accurate analysis. An optical area sensor enables the system to automatically identify different types of drums on the basis of their diameter. Finally, a shielding structure with transversal sliding doors is typically installed to protect the measurement area from unwanted background contributions.

Another common feature between ADAMOS versions, is that the mechanical parts activations are performed by a PLC, which is in its turn managed by a user-friendly Software installed on a remote PC. The Software is designed and developed by Else Nuclear, and it’s able to completely manage the whole station, from the mechanical activations, to the data acquisition and analysis, as well as status management and display. In normal operation mode, the user interacts with the system solely via the Software; the main steps would be: check of the station’s status, preliminary parameters input, and activation of the automatic cycle.

All the stations are equipped with state-of-the-art electronics components and several safety devices, to ensure the highest safety conditions for the operators and the system itself.

ADAMOS versions description

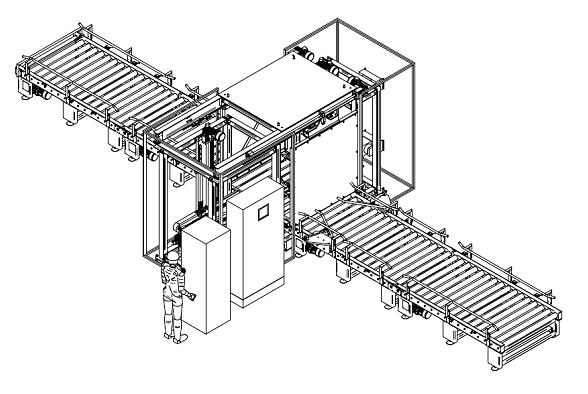

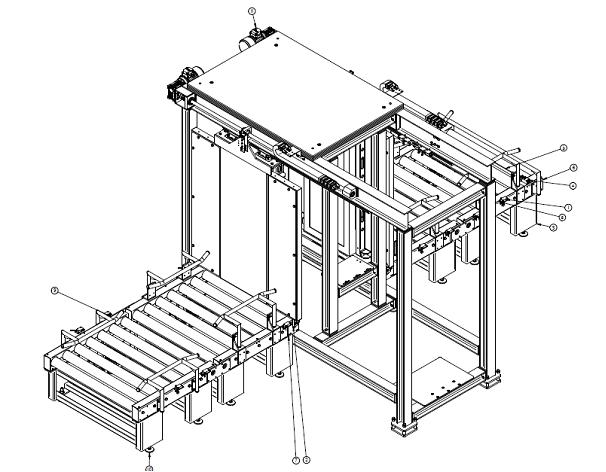

Here we will provide a particular description of each ADAMOS version: we would propose an assembly drawing of each mechanical layout, and then we shall describe its key features.

All versions described have been designed for SOGIN Spa, and destined to decommissioning activities of 3 different Nuclear Power Plants in Italy (Garigliano, Trino and Bosco Marengo).

ADAMOS - HpGe/L-D

ADAMOS - HpGe/L-D is the most complex version designed up to date.

This system is able to perform a segmented analysis of many types of drums by means of an HPGe detector. The detector can be moved both vertically, to measure different drum segments, and horizontally, in order to increase the drum-detector distance and reduce dead time in case of very high activity. Furthermore, different attenuation diaphragms can be automatically placed before the detector, depending on the dead time.

The HPGe detector is electro-cooled for maximum management ease.

An optional density measurement sub-system can be provided to estimate average densities in each segment by means of a gamma ray transmission attenuation technique using a Na-22 source. Densities up to 2 g/cm3 can be measured in a short time with a source activity as low as 10 mCi, thanks to an auxiliary NaI(Tl) detector that helps to dramatically reduce background in the transmission spectrum, thus avoiding use of huge radioactive sources with the unavoidable radiological safety issues.

Efficiency calibrations for all relevant geometries (customer-dependant) and material density up to 2 g/cm3 are pre-calculated by means of Montecarlo simulations.

Spectrometric analysis is performed by means of the renowned software ORTEC GammaVision. Raw activities are further processed in order to calculate the actual activity concentration in each segment and the whole drum. Optionally, correlated isotopes may be taken into account; correlation coefficient may be automatically recalculated for isotope decay to the date of measurement starting from a predefined early set. Multiple correlation coefficients sets can be defined, each related to a given material type and/or origin.

A further data analysis based on the integrated gamma spectra is able to locate hot spots as a function of segment and angular sector.

The different types of drums are automatically recognized by the system on the basis of their diameter. Multiple drums can be controlled in a fully automatic way (max 4 for the system shown above). All the operator must do is to load the first drum onto the input conveyor and enter identification and optional further information; then the operator can choose to activate the conveyors to advance the drum so that others can be loaded, or he can choose to directly start the measurement cycle.

A particular of the rotating platform seen from above:

ADAMOS - SCINT/L

ADAMOS - SCINT/L is equipped with the simplest detection assay of all the versions up to date.

ADAMOS - SCINT/L is designed for a fast and rough survey of drums. The measuring station features two large plastic scintillator detectors housed into the sliding doors and two side 3”x3” NaI(Tl) detectors performing spectrometry. The total gamma measurement with plastics would allow fast response while the NaI spectrometry would be required for a finer analysis.

The shown system is designed to analyze only one drum at a time.

ADAMOS - HpGe/U

ADAMOS - HpGe/U is an example of bended-path conveyors array:

This system doesn’t differ very much from the ADAMOS - HpGe/L-D, except for the mechanical layout and the lack of the density measurement sub-system. A shuttle conveyor moves the analyzed drum from the measuring station to the unloading conveyor.

The shown system is able to process 8 drums at once.

ADAMOS - HpGe

ADAMOS - HpGe is exactly the same as ADAMOS - HpGe/U, except for the conveyors array which is reduced to the minimum: there is no loading/unloading conveyor modules, the drum is directly positioned in the measurement area. ADAMOS - HpGe was not intended to measure a great number of drums, so it was unnecessary to have a long loading array like ADAMOS - HpGe/U which could hold and measure them in sequence.

Final observations

Else Nuclear has a great experience with custom-designed systems and devices. Thanks to this and to the company’s know-how, ADAMOS series systems can be adapted to any particular requirement.

This means that new versions can be designed, different from those described in this document, but sharing the same rugged and modular mechanical structure as well as the same state-of-the-art components and safety devices.

September 2014