Detectors: up to four HPGe

Free release assay of large waste containers up to 3 m3

Max payload 3000 kg

Quantitative assay of gamma emitters, and correlated scaling factors

Activity and MDA reporting

MDA (Cs-137): 0.0037 Bq/g (40 min)

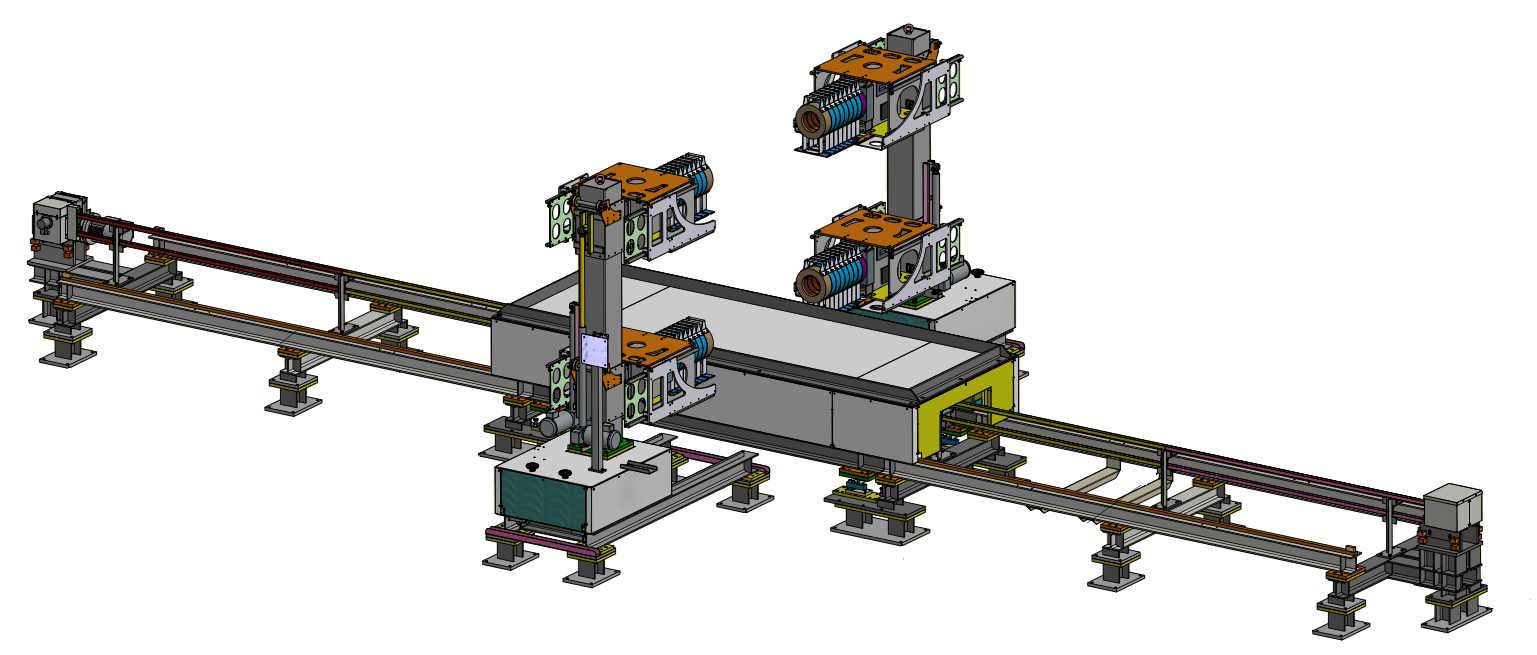

AURAS 3000 is an automated system designed to scan and characterise waste materials inside bags, boxes, drums, and B25 containers (density range: 100 – 2000 kg/m3). The system is equipped with up to four electro- or nitrogen-cooled HPGe detectors.

The main components of AURAS 3000 are:

Analysis of spectra is performed through a waste assay algorithm operating under the control of a proprietary software. The container is first positioned by crane or forklift onto the heavy-duty platform. The operator starts the procedure through the user interface, selecting the container type from a pre-set table. This results in an automated adjustment of the detector height as required by the counting geometry. The platform is then pulled towards the measurement area, where the volume of the container is scanned through a sequence of steps (sub-sections).

The system work cycle is managed by the control software, which sends commands to the PLC.

AURAS 3000 systems implement the “safety by design” principle to prevent any harm to operators and the system itself.

At the end of the measurement process, the system provides the following results: