Detectors: 4 plastic scintillators 25 x 5 x 2 cm

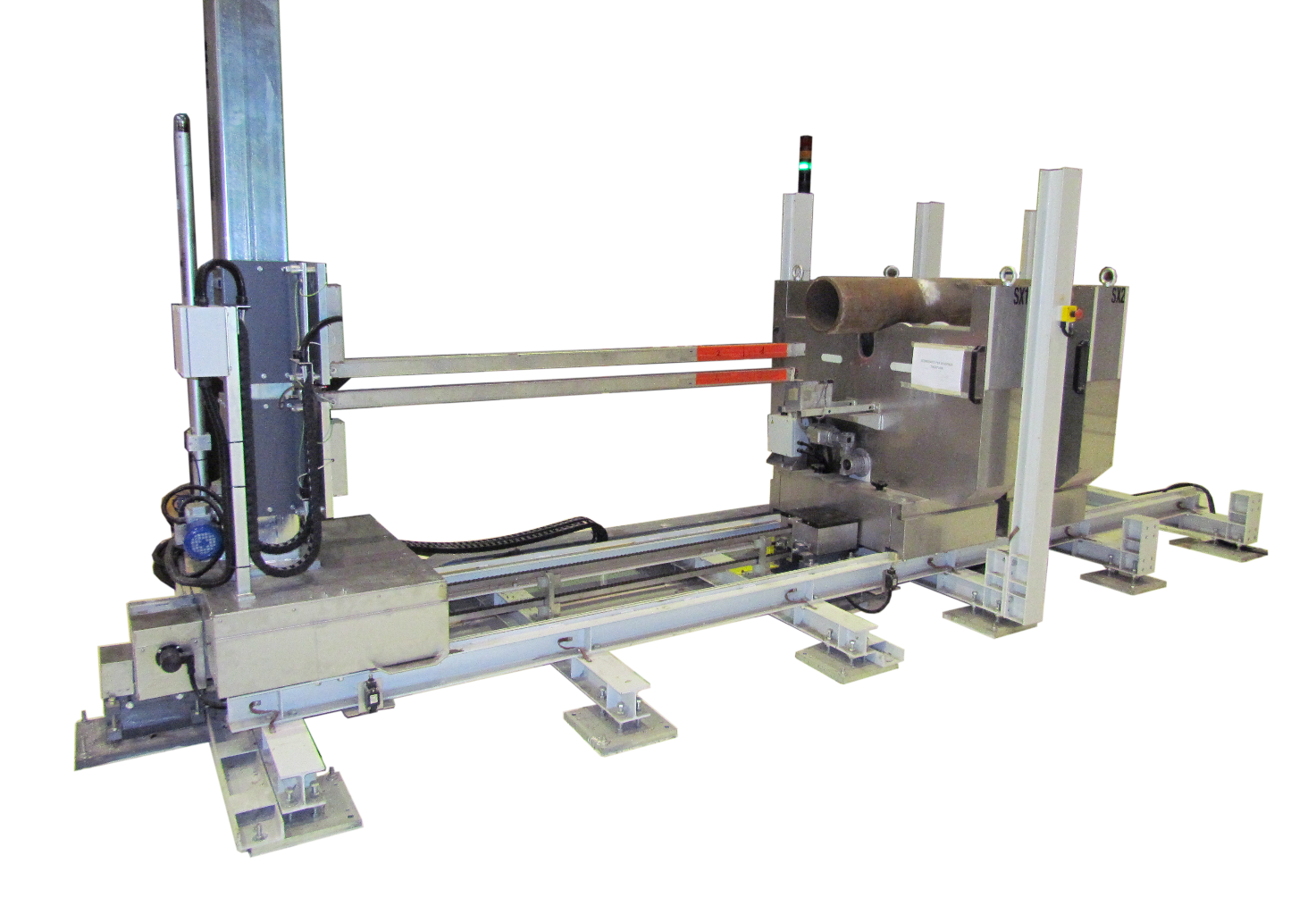

Poles support truck movable along the railway

Movable pipe lodging and rotation devices

Optical devices for surface roughness check

MDA (Co-60): 0.14 Bq/cm2 (1 min)

The PIPE SCANNER system is designed to perform a complete and accurate scanning of both the internal and external surfaces of pipes coming from decommissioning of nuclear power plants.

PIPE SCANNER is composed of:

The measurement cycle is completely automatic, carried out by a PLC and managed by the software installed on the host PC. The touch-screen user interface allows the operator to set the input parameters, the measurement settings, and to start the automatic cycle. The system status is shown both on the display and by the built-in alarm column.

After loading the pipe, PIPE SCANNER runs a series of preliminary tests through optical devices, i.e. diameter and length measurement, and roughness check. After all the preliminary checks have been carried out, the measurement cycle starts: the pipe length is automatically divided in portions to be scanned by the detectors, and the system acquires the radiometric data for each portion separately. The system can also detect hot spots of contamination. At the end of the scanning a measurement report is produced. Safety devices and a perimeter infrared barrier prevent any dangerous man/machine interaction.

The lodging supports are two robust structures manually movable on the railway; they can be fastened through manual brakes in a proper position according the length of the pipe. In each support there is a pair of compass rollers: when the work cycle starts, they lift up the pipe and put it into rotation around its axis, at a proper speed depending on its diameter.

The plastic scintillators are installed in pairs in the tip of two poles, mounted on the support column, in order to “see” both the pipe’s surfaces, internal and external. The support station moves along the railway in order to scan each sub-section of the pipe.